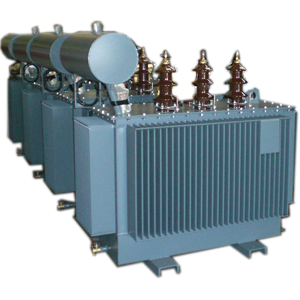

Special Application Transformer

A number of industry applications require specific industrial transformers due to the usage of power(current) as a major resource for production. We at Aarambhi industries manufacture Special Application Transformers as below

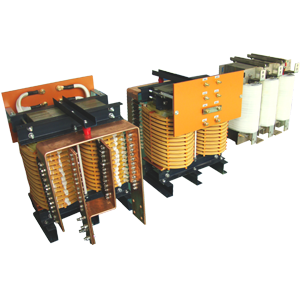

- - Electric arc furnace transformers (EAF)

- - DC electric arc furnace transformers (DC EAF)

- - Rectifier transformers

- - Converter duty transformers

- - Line Feeder

- - Isolation Transformers

- - Lighting Transformers

- - Ultra Isolation Transformers

TECHNICAL SPECIFICATIONS |

||

|---|---|---|

| Rating | Upto 5 mVA | |

| Duty Type | Outdoor/Indoor, Pole or Ground Mounted | |

| Voltage Class | 33.3,6.6,11,22,33 kV or any specific | |

| No Of Phases | 1 or 3 phase | |

| Frequency | 50/60 Hz | |

| Vector Group | Dyn1 or Dyn5 or Drn11 or any specific | |

| Insulating Fluid | PCB FREE Mineral Oil, both inhibited & uninhibited, as per IS/IEC and customer requirement as well | |

| Cooling Medium | Oil/Dry Type | |

| Tap Changer | Off Circuit or On Load | |

| Tapping Range | + 2.5% X 2 for OCTC or + 1.25% X 4 & -1.25% X 8 for OLTC or as per customer requirement | |

| Winding Material | Aluminium Or Copper with multi paper covering | |

| Applicable Standards | IS 2006,IEC76,ANSI,IEEE | |

| Painting | Enamel, Epoxy, Polyurethane, 10 Tank Powder Coating or customer specific | |

| Tank | Hermetically Sealed, Corrugated Radiator Type or Conventional rectangular tank type | |

SALIENT FEATURES OF MAKE SPECIAL APPLICATION TRANSFORMERS |

|

| - Custom made to meet each and every requirement of customers conforming to National & international Standards | |

| - Designed by experienced expert engineers using most modern software | |

| - Highest dielectric insulation property to withstand Lightening Impulse | |

| - Step lap core design with multiple sheets per bag used in the core lamination jointing | |

| - Designed using advanced software like AutoCAD & ProE to ensure adherence to the design parameters | |

| - Pre composed Insulation material for minimal moisture absorption | |

| - In House Fabrication with Laser and CNC machines | |

| - Integrated 10-Tank Powder coating process | |

| - Facility to make 500 Nos Transformers per month | |